|

The heart of the

system, the starting point of all our products, can beat at a rate of

almost ten beats per minute.

It is a 150/60 tons hydraulic arch press; in this example it mounts a

rather complex die set, that is capable of performing in one single

action all the processes needed to obtain the finished component.

|

|

The pre-stained steel

sheet is pushed forward by a rolling apparatus which, when needed, can

also be used as straightener or curling machine

|

|

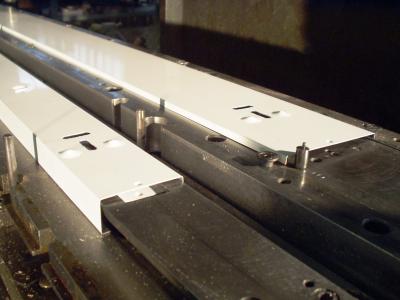

The reglette comprises

two c-shaped shells, front and back of the fixture, equally sized but

bearing a different pattern of holes.

The pictures show the die set configured for making the back (it is

possible to see the holes that will allow the fastening to the ceiling).

The two stampings needed in order to make the undercut are carried

out simultaneously.

Keep scrolling if you

wish to see the details of the stamping, otherwise click here

|

|

The operator removes

the finished part ...

|

|

... moves the piece

that has undergone the first stamping onto the anterior part of the die

set ...

|

|

... pressing on a pedal

switch, the operator gets a new section of steel sheet positioned on

the posterior part of the die set.

|

|

The sheet on the right

is ready to undergo the first edge bending, whereas the piece on the

left will be bent in the C shape and punched.

|

|

During all phases,

stamping is controlled by the operator. It is the worker that sets the

timing, not the machine.

|

|

Once the die set is

risen there is a complete back half, a piece with the first bending and

the free end of the steel sheet already carries the holes that will

correspond to one of the two heads of the complete fixture.

The

cycle starts again.

|

|

Once completed, the

pieces can either go straight to the wiring station or can be

stockpiled.

|

|

Wiring begins by

fastening some components to the fixture using a compressed air riveter

|

|

Wiring and packing are

normally carried out by the same operator.

|

Continue

the tour

|

Go

to the catalogue

|