Consorzio RFX

The

Consorzio

RFX was set up in 1996 by CNR, ENEA, University

of Padova and Acciaierie Venete S.p.A. (local industry),

and in 2005 by INFN, in order to strengthen and give

a more stable organization to the Padua Research Group

commited to plasma and controlled thermonuclear fusion

research already since 1958. The

Consorzio

RFX was set up in 1996 by CNR, ENEA, University

of Padova and Acciaierie Venete S.p.A. (local industry),

and in 2005 by INFN, in order to strengthen and give

a more stable organization to the Padua Research Group

commited to plasma and controlled thermonuclear fusion

research already since 1958.

The consortium designs, developes and realizes high

technology equipment and devices devoted to scientific

and technological research activity in the field of

thermonuclear fusion as a possible source of alternative

energy. Among its main activities, it developes the

RFX Experiment, the largest machine worldwide for the

study of the plasma physics in the Reversed Field Pinch

configuration, and developes and realizes the Neutral

Beam Injector (NIB) prototype for the experimental fusion

reactor ITER.

The consortium prompts the cooperation between the

partners and industrial environment upon the specific

areas of activity.

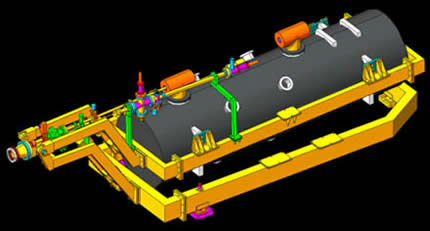

We

have been called to collaborate with Consorzio RFX for

the 3D design and layout verification of the support

structure components of the pellet cryogenic injector

for the RFX experiment. We

have been called to collaborate with Consorzio RFX for

the 3D design and layout verification of the support

structure components of the pellet cryogenic injector

for the RFX experiment.

The function of the structure is to support, position

and regulate the components which launch solid "projectiles"

within the discharge room, in an appropriate maner and

avoiding collisions or interactions with the system's

components. The vaporization of such projectiles allows

for the process gas density regulation, allowing also

for the diagnosis of the plasma physical conditions

within the toroidal magnetic restrain.

Sharing the same modelling platform (I-DEAS), the activity

was performed integrally with the company's developing

procedure and the associativity with the components

defined previously was maintained. The activity was

complete from the production of constructive assembly

drawings and the detailed parts developed.

|